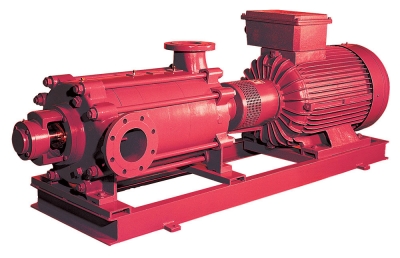

High Pressure Multistage Centrifugal Pumps KME

Description:

• HME series pumps have horizontal axis, radial separable body and are multistage centrifugal pumps that can be dismantled in stages.

• Closed type impellers are situated between bearing and are balanced dynamically.

• Impeller balance is achieved with back wear rings and balance holes. A balance disc or drum can be used for very high pressures.

• HME series includes 5 types depending on stage number, rotation speed, maximum flow rate and vary between 2-15 stages.

• In standard manufacture, the pump and the motor are connected by means of a flexible coupling on a single base plate. In standart assembly the discharge port is at the other side with flange oriented towards the left. Alternative Designs can be obtained upon request.

• Suction and discharge flanges can be situated on the left, right and on the top. On special order, the suction flange can be positioned at the motor end. In that case motor rotation would be in a counter-clockwise direction.

• HME series pumps have horizontal axis, radial separable body and are multistage centrifugal pumps that can be dismantled in stages.

• Closed type impellers are situated between bearing and are balanced dynamically.

• Impeller balance is achieved with back wear rings and balance holes. A balance disc or drum can be used for very high pressures.

• HME series includes 5 types depending on stage number, rotation speed, maximum flow rate and vary between 2-15 stages.

• In standard manufacture, the pump and the motor are connected by means of a flexible coupling on a single base plate. In standart assembly the discharge port is at the other side with flange oriented towards the left. Alternative Designs can be obtained upon request.

• Suction and discharge flanges can be situated on the left, right and on the top. On special order, the suction flange can be positioned at the motor end. In that case motor rotation would be in a counter-clockwise direction.

Fields of Application

• Pumping stations.

• Water supply in high buildings

• Water treatment systems

• Industrial washing processes

• Fire fighting systems

• Boilers and condenssation process

• Health and hygienic processes

• Industrial and public applications

• Water distribution systems

• Marine, metallurgy, energy sectors

• Irrigation systems

Pumped Liquids

Thin, clean, non-aggressive and non-explosive liquids free from solid particles and fibres.

Fresh water, potable water, boiler feed water, industrial water, sea and brackish water, hot water,

condensate, lye, etc.

For special applications, please consult us.

Design

• The HME Pump has horizontal axis, radially split, ring section design multistage centrifugal pump of non-self priming type.

• Impellers are between bearings, single entry, closed type and dynamically balanced. Impeller diameter will be corrected for optimal adherence to the required duty point.

• For balancing the axial thrust, all impellers have back wear rings. For high pressure, balance disc application is used.

• The pump series consists of 5 sizes. HME 80, 100, 125, 150 and 200. Stages are from 2 up to max. 15 stages.

• Pump and motor are fitted on a common base plate and connected to each other via flexible coupling.

• Normally, discharge part is at motor side on the top and suction part is at dead end side on the left viewed from driver.

• Suction and discharge nozzles may be a choice of three 90° positions. By special request, it is possible to put the suction nozzle at the motor side. In this arrangement pump and motor rotation must be counter clockwise.

Published in

Industrial Pumps and Fire Fighting Units

©

2015 - 2019

Ticariyer KP